Remote Fiber Monitoring System in Modern Fiber Network

June 23, 2025

Decoding 5G Jargon!

September 12, 2025

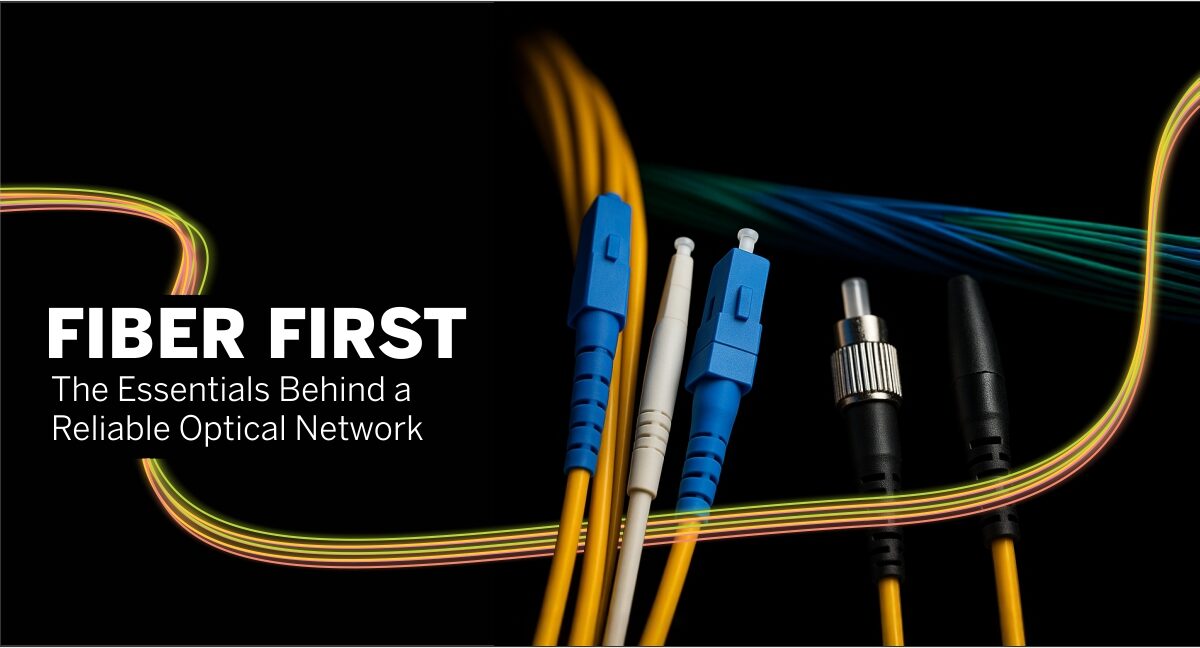

Fiber‑optic communication is the backbone of modern telecommunication networks, offering high‑speed data transmission with minimal loss over long distances. Three crucial factors that determine the performance and reliability of a fiber‑optic system are the type of fiber, the type of connector, and the cleaning procedures used for connectors.

Types of Fiber

Fiber‑optic cables fall into two broad categories—single‑mode and multimode—each suited to different applications.

- Single‑mode fiber (SMF):

Single‑mode fiber has a small core diameter, typically around 8–10 µm. It allows only one mode of light to propagate, minimizing signal attenuation and dispersion. SMF is ideal for long‑distance communication and is commonly used in telecom backbones, the Internet backbone, and high‑speed data centers. - Multimode fiber (MMF):

Multimode fiber has a larger core diameter—generally 50 µm or 62.5 µm—that lets multiple light modes propagate simultaneously. It is best suited for short‑distance communication within a building or across a campus. MMF is cost‑effective for local‑area networks (LANs) and audio/video applications.

Performance grades include OM1, OM2, OM3, and OM4 for MMF, and OS1 or OS2 for SMF.

Types of Connectors

Connectors join fiber‑optic cables while preserving signal integrity. Common types include:

- SC (Subscriber Connector):

A square, push‑pull connector widely used in telecom and data networks for its reliability and ease of installation. - LC (Lucent Connector):

A small‑form‑factor connector that resembles a mini‑SC. LC connectors excel in high‑density patch panels and data centers. - ST (Straight Tip):

A bayonet‑style, twist‑lock connector once popular in legacy networks, especially with multimode fiber. - MPO/MTP:

Multifiber push‑on connectors that support up to 24 fibers in a single ferrule, essential in modern 40 G, 100 G, and 400 G networks.

Connector choice depends on the application, environment, and required performance specifications.

Cleaning Connectors

Connector cleanliness is vital for optimal signal transmission; microscopic dust or oil can cause significant loss or damage to the fiber end face.

Cleaning procedures

- Dry cleaning:

Use lint‑free fiber‑optic cleaning sticks or reels designed for connectors. Gently wipe the end face to remove dust and loose particles. - Wet‑to‑dry cleaning:

Apply 99 % (or higher) isopropyl alcohol to a cleaning swab or wipe, then follow with a dry wipe. This method removes oils and stubborn residues. - Automated cleaners:

Handheld or benchtop devices that clean connectors with a single click, ensuring consistency and speed.